Our services are not limited to the below listed ones. We provide other services for a wide range of applications and situations with special requirements to inspections. Solutions provided by us are usual tailored to the specific requirements of the inspection.

CUI is a significant problem for industrial plants. On the surface the condition of the object may look fine; underneath there is often corrosion which leads to problems such as leaking. For this reason, CUI inspection is essential.

One method of CUI inspection is a screening technology. Screening is not a detailed inspection but it can quickly detect corrosion under insulation. Once CUI is detected by the screening process, a detailed inspection can be carried out. This is an efficient way to inspect CUI.

RTD-Incotest is a CUI inspection by means of relative comparison. When one inspection point is defined as a reference point, the result of the other inspection point is calculated with the reference.

OpenVision™ – OVCF is a Hand-Held Real-Time X-Ray system for CUI inspection to look for corrosion on a pipe surface.

The result of the inspection is captured as a video and/or photo file, an easy way to recognize the pipe’s condition.

Robotic inspections offer many advantages. Eliminating the need for scaffolding leads to cost reduction as well as increased safety for workers. Continuous inspections can be performed with robotics, with the ability to take on a huge workload in a reliable and efficient way.

We can introduce the following robotics inspection solutions. Both solutions have great advantages compared to conventional inspection methods carried out by engineers.

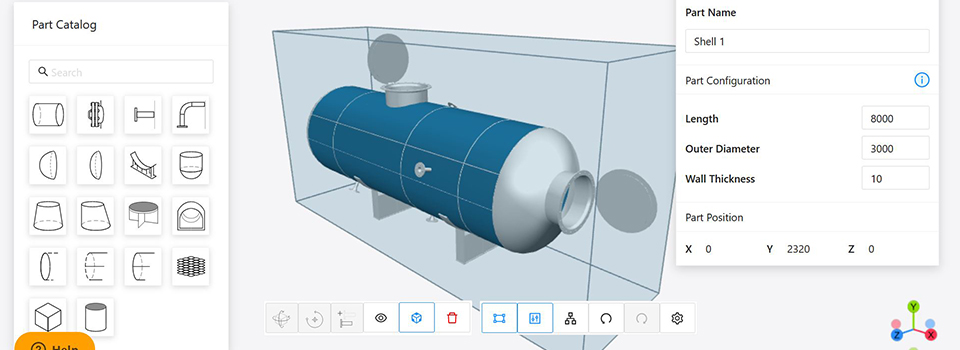

The Bike Platform is cutting-edge robotics technology. It can be driven on a complex object surface and can capture the wall thickness measurement and visual inspection.

One of the most reliable and widely-used inspection solutions for the global pipeline industry. It is possible to inspect the wall thickness and search for defects from a 6-inch to 64-inch diameter pipeline.

Every client is faced with different inspection problems. A solution that works for one company does not necessarily work for another. To meet specific inspection requirements, we would like to suggest a tailor-made inspection solution. We are willing to find a solution within our global network to meet our client’s requirement.

Depending on the object, work environment and inspection requirement, we can suggest a suitable robotics solution.

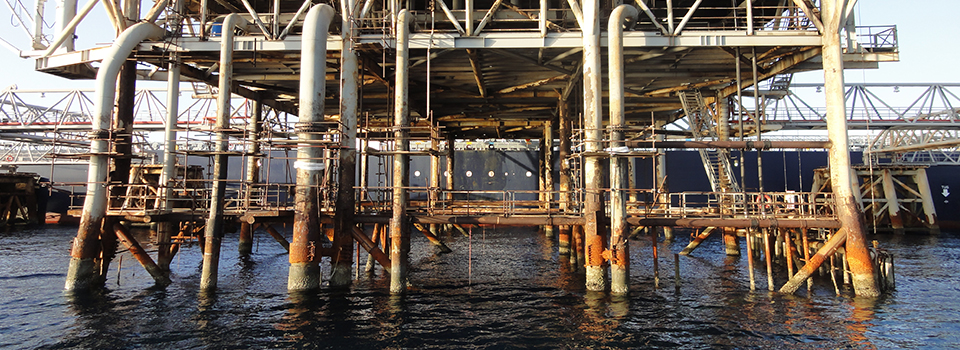

Subsea environments pose difficult conditions for inspection compared to onshore environments.

We specialize in subsea inspections and can support your subsea inspection needs.

Each country and area have their own industrial standards.

By using our global network, we can offer our services to help adhere to the the required standards.