Bike

Mobile inspection and maintenance robotics is a fast growing industrial market. One of the main advantages of mobile robots is that they can reach locations inaccessible by humans because of size constraints, temperature, immersion in liquids or safety reasons. Certified and experienced engineers today enter and “look” at the predefined locations to take pictures for reporting. Beside very expensive organizational issues such as watchmen and ventilation this procedure is very dangerous for the experts.

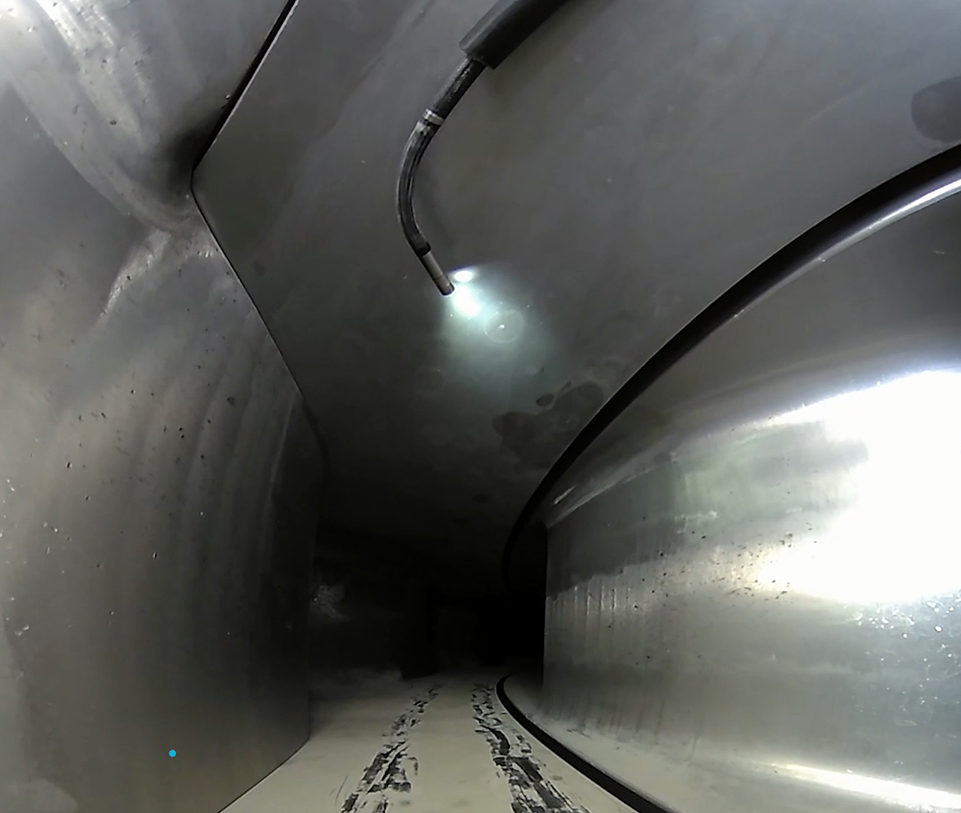

In this framework, the BIKE inspection robot has been developed. The BIKE platform is a magnetic wheeled robot capable of inspecting power plant facilities and multiple applications in the oil&gas industry, such as vessel or pipe inspection.

With the BIKE platform Inspection Robotics has realized a truly ultra-mobile inspection platform. Where existing inspection crawlers are reaching their limits in terms of accessibility and maneuverability the BIKE platform is just beginning to perform.