Guided Ultrasonic

Guided Ultrasonics Limited (GUL) was established in 1999 by members of a research team at Imperial College’s Mechanical Engineering Department and is now the global leader in the provision of guided wave pipe testing equipment, training and services.

Guided Wave Testing (GWT) is a relatively new non-destructive testing (NDT) method, which has been pioneered by GUL since its incorporation and the company has led the way in setting the standard for pipeline inspection and monitoring globally.

GUL is committed to continuous improvement to meet the needs and expectations of clients as well as the wider industry.

Guided waves are used in rapid testing or screening tools to detect, locate, and classify corrosion defects.

Large sections of piping can be quickly screened with 100 percent volumetric coverage to determine precise locations of corrosion damage.

Inspection:

Using guided waves, long lengths of pipes can be remotely inspected for many different types of defects.

One hundred percent inspection allows an on-site inspector to quickly locate critical areas of pipework and perform any follow-up investigations that are necessary to provide the required inspection information.

Monitoring:

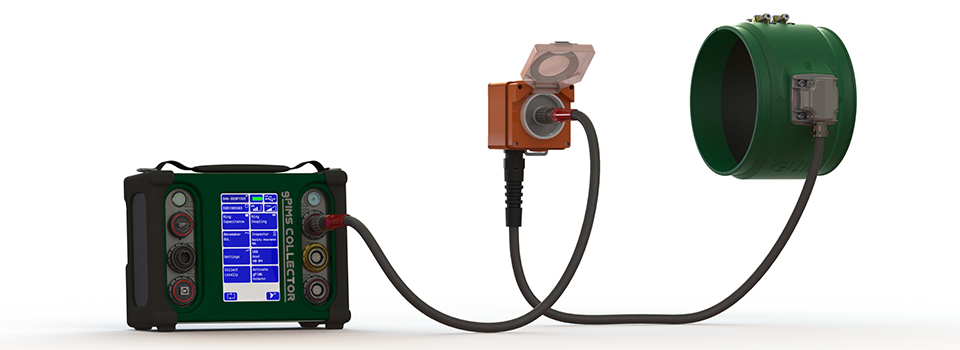

Permanently installed gPIMS® sensors allow critical sections of pipelines to be regularily and efficiently monitored. Regular data collection from fixed positions greatly enhances the power of guided waves.