BRIC

Water walls (tubes welded to tubes in parallel) in boilers need to be inspected on a regular basis carrying out a visual inspection and a wall thickness measurement. To avoid time consuming scaffolding , especially for partial inspection, an automated system for water wall inspection and cleaning was designed by Inspection Robotics in collaboration with our partners.

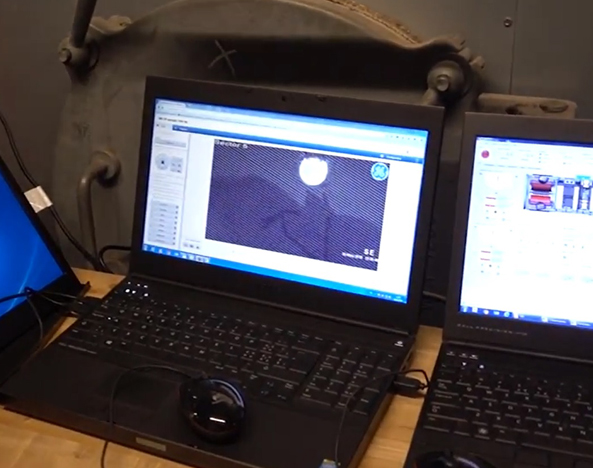

The core element of the inspection system is a crawler with 4 magnetic rollers. The magnets can be swiveled to allow for safe handling as well as to be able to cross wall transition (up to 90°). The crawler carries several waterjet nozzles fed by a water pump outside the boiler. A dedicated deployment crane allows the operator team to safely deploy the 80kg crawler into the boiler.